CIP Plants

A CIP plant is a smart cleaning system that washes the inside of dairy machines and pipes without anyone having to take them apart. The name stands for Cleaning-In-Place, and it works by pumping water and special cleaning liquids through the entire factory setup. By using the right amount of heat and flow, the plant removes any leftover milk or germs. Everything is built from strong stainless steel, which is safe for food and very easy to keep clean. This automatic way of washing ensures that every corner of the pipes is reached, which provides much better hygiene than cleaning by hand. Because the machines stay closed during the process, it is a very safe and tidy way to maintain a spotless dairy environment.

Using a CIP plant helps a business save a lot of time and reduces the need for hard manual labor. Instead of workers scrubbing parts for hours, the system follows a set program to rinse, wash, and sanitize everything perfectly. This regular cleaning is important because it keeps the milk quality safe and ensures every product tastes fresh. Since the system is easy to operate, there are fewer mistakes, and the factory can start working again much faster. These plants are designed to be reliable and help the dairy run smoothly every day. By using this modern technology, companies can focus on making high-quality food while the CIP plant takes care of the hard work of keeping everything pure and healthy.

Manual CIP System

Semi-Automatic CIP System

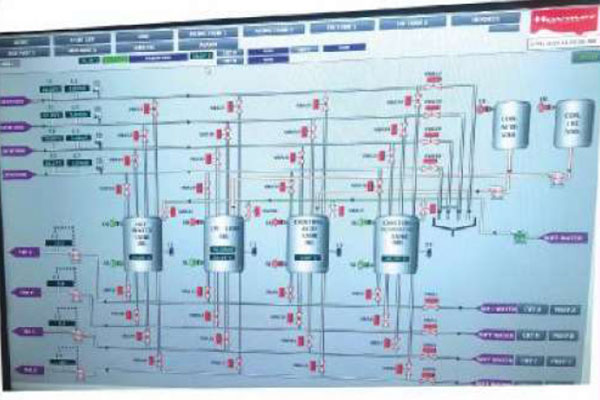

Fully Automated C.I.P. System (PLC & SCADA Based)