Milk Reception, Pasteurization, Storage & Packing Section

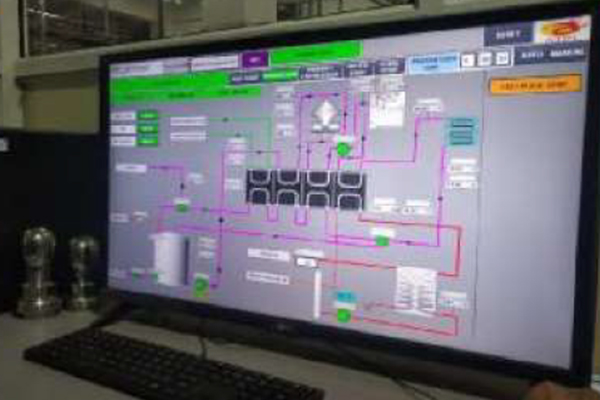

The process begins when fresh milk arrives at the reception area, where it is tested to make sure it is healthy and pure. Once it passes these checks, the milk flows into a pasteurization machine. Pasteurization is a very important step where milk is heated quickly and then cooled down to kill any tiny germs. This makes the milk safe to drink and helps it stay fresh for a much longer time. The entire system is made of shiny stainless steel, which is a special food-grade material that stays very clean and does not rust. After the milk is safe and clean, it moves through pipes into large storage tanks. These tanks act like giant, clean refrigerators that keep the milk at the perfect temperature until it is ready to be put into bottles or bags.

In the packing section, the milk is measured and sealed into clean containers by smart machines.

This final step is very important because it protects the milk from the outside air and keep it fresh for families to enjoy. The whole dairy plant is designed for a smooth flow, meaning the milk moves from the truck to the package without any messy stops. Because the machines are easy to wash and follow strict safety rules, the quality of the milk stays exactly the same every single day. Using these professional machines ensures that the workspace remains spotless and the food stays safe. This careful process helps dairy companies provide high-quality milk that tastes great and is always healthy for everyone.

Milk Reception & Chilling & Equipments

Tanker Reception

Skid Mounted Pasteurization Module

Skid Mounted Pasteurization Module

Skid Mounted Pasteurization Module

Overhead Process Milk Tanks

Skid Mounted Pasteurization Module

Pouch Packing Section